As global demand for high-specification construction materials and industrial fillers escalates, Shanghai Clirik Machinery Co., Ltd. is decisively addressing the industry’s need for greater efficiency and particle uniformity with its advanced HGM Ultrafine Grinding Mill series. This sophisticated equipment represents a generational leap in mineral processing technology, strategically revolutionizing how raw gypsum rock is transformed into consistent, premium-quality Gypsum Powder across the globe.

I. Technical Superiority: Precision Engineering for Performance

The HGM Grinding Mill is not an adaptation of existing technology; it is a dedicated system engineered for micro-powder production, specifically targeting minerals with Mohs hardness ≤6, such as gypsum.

A. The Multi-Stage Grinding Mechanism

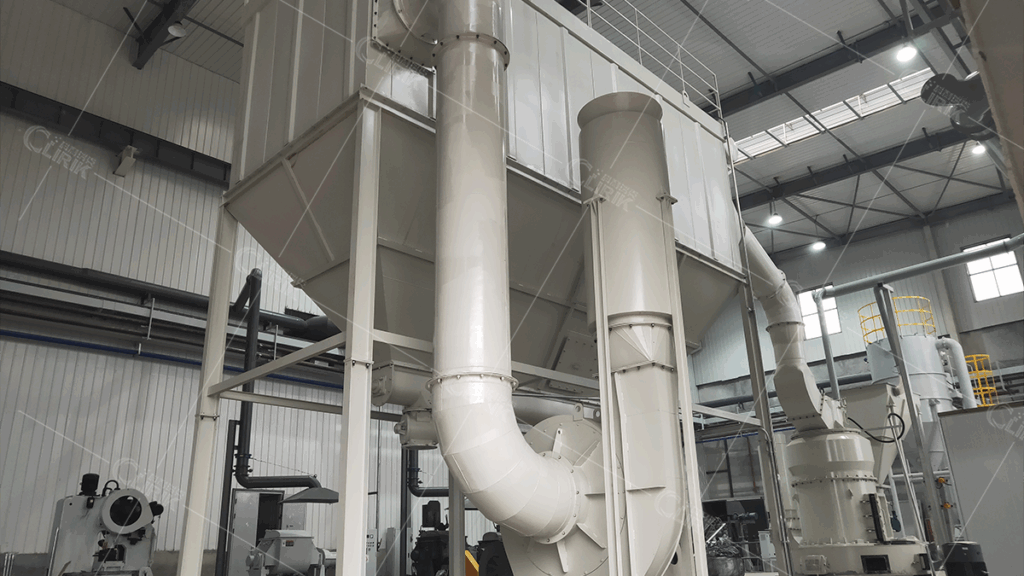

The core innovation lies in the mill’s dynamic structure, which integrates crushing, grinding, and classifying into a single, highly efficient process.

Optimized Grinding Cavity: The mill employs a vertical structure where the grinding rollers exert centrifugal force against the grinding ring. Unlike older models, the HGM utilizes a specialized pressure-increasing mechanism, often involving high-pressure springs and multi-lever systems, which dramatically enhances the grinding pressure. This optimization ensures maximum material comminution with every rotation, leading to a finer product with fewer passes.

Fine Particle Separation: The integrated High-Efficiency Powder Classifier, powered by a variable frequency motor, is the brain of the operation. It allows for the real-time adjustment of air velocity, enabling operators to “cut” the powder stream with precision. Unground material is immediately cycled back to the grinding chamber, achieving virtually 100% material utilization and guaranteeing that the finished Gypsum Powder meets the target specification, ranging from 325 mesh (47μm) down to an impressive 2500 mesh (5μm).

B. Energy Economics and Environmental Stewardship

The HGM mill is a champion of sustainable manufacturing, offering substantial economic benefits:

Significant Energy Savings: The streamlined air circuit and reduced rotational resistance contribute to an average power saving of 30% to 40% compared to equivalent traditional Raymond or pendulum mills. For a continuous production plant, this translates into millions in annual operational expenditure reduction.

Minimal Environmental Impact: The entire grinding and conveying system is designed as a fully enclosed, negative-pressure loop. Coupled with a sophisticated pulse jet dust collector system, dust emissions are rigorously controlled to meet or exceed the most stringent international standards, positioning the HGM mill as the ideal solution for environmentally conscious manufacturers.

II. Market Impact: Unlocking High-Value Gypsum Powder Applications

The consistent, ultra-fine quality of the powder generated by the HGM Grinding Mill is indispensable for modern high-value applications, enabling customers to tap into premium markets.

| Gypsum Powder Fineness | Application Sector | Product Examples | Value Proposition |

| 325-600 Mesh | Standard Construction | Plaster of Paris, Gypsum Blocks | High capacity, rapid setting time. |

| 800-1250 Mesh | High-Strength Specialty | Gypsum Self-Leveling Mortars, High-Density Boards | Superior flowability, higher compressive strength. |

| 1500-2500 Mesh | Industrial/Chemical Filler | Polymer Fillers, Fine Coatings, Dental Plaster ($\alpha$-Gypsum) | Optimal particle packing, extreme smoothness, purity. |

By achieving fineness levels previously only possible with costly, lower-throughput jet mills, the HGM Grinding Mill democratizes access to premium-grade Gypsum Powder, allowing manufacturers to improve the performance metrics of their end products, such as reducing water demand in mixes and enhancing surface finish.

III. Maintenance and Longevity: Maximizing Uptime

Clirik’s design philosophy prioritizes longevity and ease of maintenance. Key wear parts, notably the grinding rollers and ring, are engineered using advanced high-manganese steel and specific composite alloys. This material science innovation dramatically extends the service life of wear parts, in some cases by more than 50% compared to standard alloys, resulting in far fewer planned and unplanned stoppages. The centralized lubrication system also allows for routine maintenance without long production halts, maximizing production uptime and ensuring consistent supply.

In conclusion, the CLIRIK HGM Grinding Mill is more than just processing equipment; it is a strategic investment that delivers technological superiority, economic efficiency, and environmental compliance, securely positioning its users at the forefront of the global Gypsum Powder market.